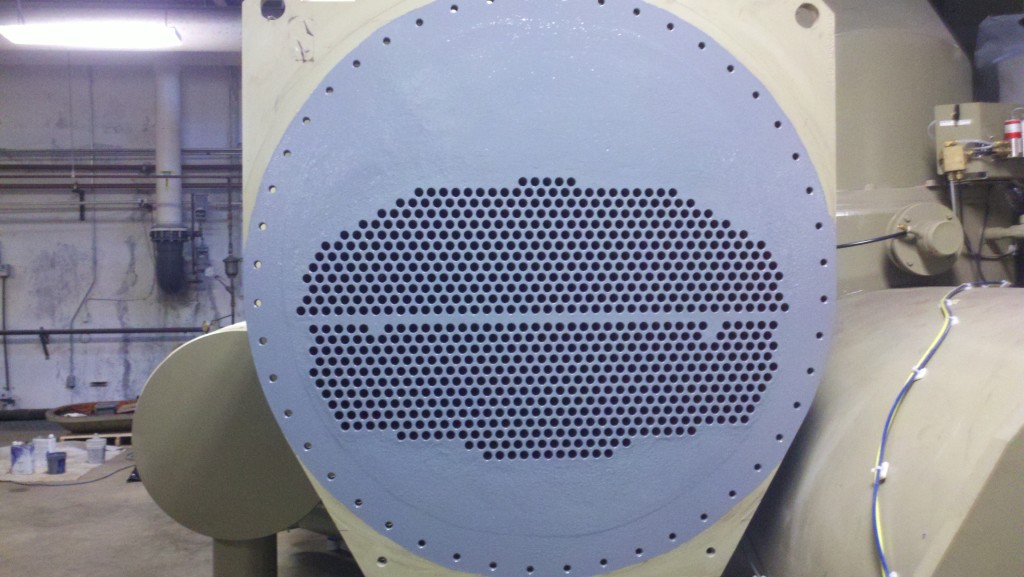

Tubesheet Rebuild & Repairs

National Engineering Epoxy Tube Sheet Cladding System are in high demand in Industrial Plants, where heating and cooling of process liquids is required.

Many times the chemicals or air that is being used in these heat exchangers is very aggressive and may cause corrosion. Premature failure of the heat exchangers is caused by high temperatures. National engineering has the expertise and experience in rebuilding these types of heat exchangers.

We own the proprietary blasting plugs and coating plugs that protect your tubes during surface preparation. We also use high temperature ceramic filled Epoxy materials to restore the geometry of your existing heat exchanger.

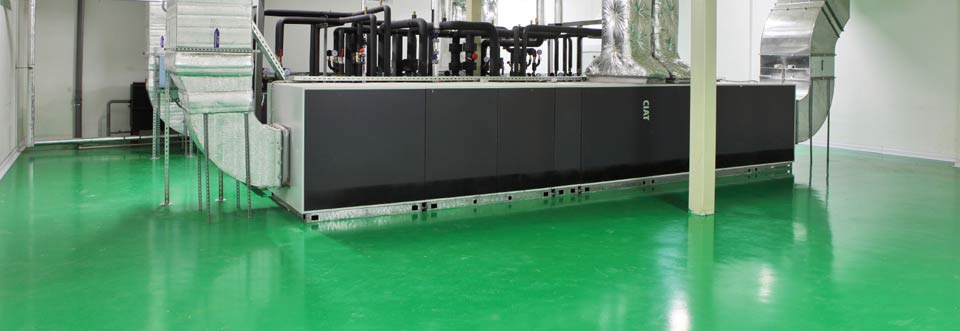

Chiller Coating System

Chillers are one of the crucial components in many large modern buildings. The tube sheets on the stealer’s are highly susceptible to corrosion.

The most common form of corrosion is bimetallic corrosion, the difference in the metallurgy between the copper tubes and the mild steel tubes causes corrosion to occur at the most critical point which is the tubesheet/cooling tube interface.

National Engineering’s Chiller Coating System will quickly and completely resolve the problem of bimetallic corrosion.

We use high quality 3M, Belzona, Chesterton ARC, and Duromar epoxy coatings.

Note: National Engineering manufactures special plastic blasting plugs that protect the interior of the cooling tubes during surface preparation. We also manufacture the special coating plugs used in the reforming of the tube sheet. Please contact us if you would like to purchase any of these plugs or our specialty epoxies.

Cooling tower – both metal and concrete cooling towers are under constant attack from chemicals and the environment. These critical pieces of equipment can easily protected with our resinous coating systems. The installation of these products can be professionally done in a very short period of time. Please contact us today to help you determine what is the right solution for your problem.