At National Engineering we understand that the right floor is not always a coated floor. Sometimes you our customer have a need for polished concrete.

Polished concrete offers many benefits. We use our large diamond grinding system which is attached to HEPA vacuums to give a dust free installation of your polished floors. Properly polished concrete will provide many years of service and a high level of shine, with ease of care and maintenance.

Advantages/Benefits

- Marble like shine

- Ease of Maintenance

- LEED Qualified

- Abrasion Resistance

- Eliminated Dusting

- Slip Resistant

Ideal For

- Commercial

- Industrial

- Schools

- Healthcare

- Warehousing

- Aviation

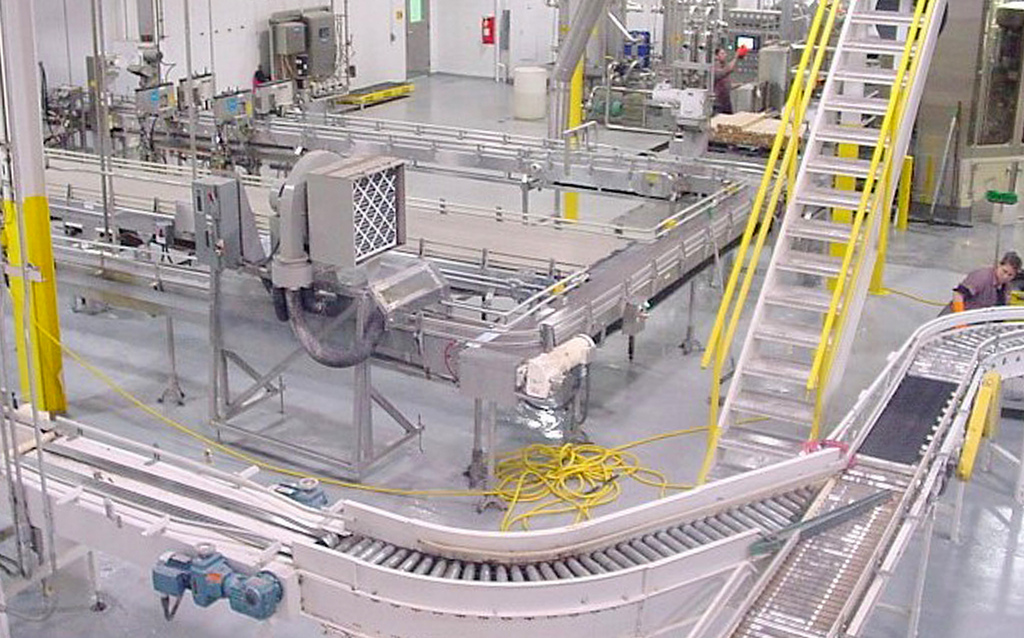

- Packaging Plants

- Food & Beverage

- Manufacturing Plants

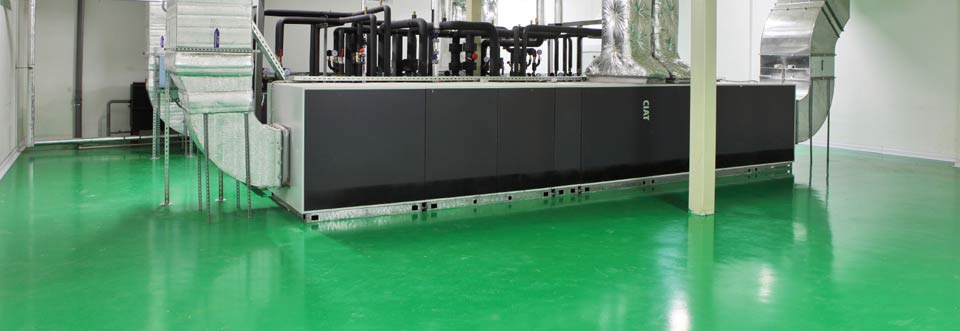

- Clean rooms

- Maintenance shops

- Laboratories

- Warehouses

- Cafeterias

National Engineering offers two types of polishing options.

Heavy duty polished concrete requires the use of heavy planetary diamond grinders to shine the concrete. These special machines provide the highest quality of polishing, but also take more time to achieve these results. This type of polishing is more expensive because of the equipment and time required.

Industrial polished concrete requires the use of our large ride on equipment that polishes concrete at a higher production rate. These machines typically do not have the same amount of down pressure and produce a lower gloss and shine. This is an economical solution for large concrete warehouses and floors.

National Engineering Optional Additional Services in Polished Concrete:

- Stain and Color Polish

- Concrete Burnish

- Concrete Guard Products